Achieve perfection with our screen stretching solutions in New Zealand

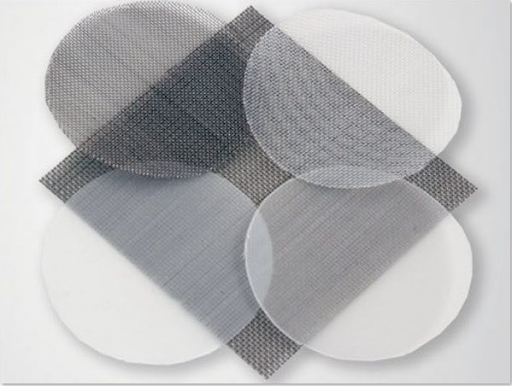

ADM Services provides innovative screen stretching solutions to meet the needs of businesses all over New Zealand. With our full range of services, you can rest assured that your screens will stay clean and working properly, so you can focus on what’s important – managing your business. ADM Services understands the importance of smooth operations. That’s why we use cutting-edge technologies and equipment to solve screen stretching issues effectively and efficiently. Whether you’re dealing with a small distortion or a large stretching, our experts can handle it all with accuracy and proficiency.

Our Services

Non-Food Manufacturing Industry

We offer re-meshing of any frame type or size (circular, square or rectangular). Mesh Typically used – 316 Grade Stainless Steel. Grade 316 has excellent corrosion resistance in a wide range. Its main advantage over grade 304 is its increased ability to resist pitting and crevice corrosion in warm chloride environments. Typical applications for 316 are structural members, architectural components particularly in industrial environments: food and beverage processing equipment, hot water systems, and equipment for chemical, Petro-chemical, mineral processing, and other industries.

- Bonding – water and chemical resistant

Milling Industry

We offer re-meshing of any frame type, shape or size (wooden, aluminium, or stainless steel). Re-meshing frames can allow alternative mesh to be fitted, enabling adjustment to screen performance and throughput. Food compatibility – Nylon and Metal mesh used are made from yarns that contain only substances recognized as safe for contact with food.

- Bonding - FDA compliant

Water Filtration Industry

We offer re-meshing of any frame type or size (metal frame or plastic frame). Mesh Typically used – Nylon Mash.

- Bonding – water and chemical resistant

Food Manufacturing Industry

We offer re-meshing of any frame type, shape or size (circular, square or rectangular). Mesh Typically used – 304 Grade Stainless steel Mesh. Grade 304 had excellent corrosion resistance in a wide range. It resists ordinary rusting in most architectural applications. It is also resistant to most food processing environments, can be readily cleaned, and resists organic chemicals, dye stuffs and a wide variety of inorganic chemicals. Typical applications for 304 includes architecture, food and beverage processing, equipment and utensils, commercial and domestic kitchen construction, sinks, and equipment for chemical, petrochemical, mineral processing, and other industries.

- Bonding - FDA compliant

- Nylon Mesh and Woven Wire Mesh – FDA and EU compliant

Why Re-mesh?

If your mesh breaks, is low in tension or is damaged, remeshing is an economical alternative to replacing the entire mesh frame. Simply return your frame to us and we will re-mesh it, saving you the cost of a new screen or sieve. Each damaged frame is carefully cleaned before rescreening to remove contaminants and maintain your product quality. We re-mesh a complete range of frame sizes and shape for all industries and offer different meshes to ensure you achieve optimum sieving accuracy.

- Maintain your screening accuracy.

- Reduce your costs.

Other Needs

If you have any other re-meshing needs not specified above or specific requirements, please contact us